"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

09/10/2016 at 12:46 ē Filed to: None

6

6

6

6

"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

"Dash-doorhandle-6 cyl none the richer" (dash-doorhandle-and-bondo)

09/10/2016 at 12:46 ē Filed to: None |  6 6

|  6 6 |

cowl rot, also crooked from factory, will never, ever, get a straight passenger door.

cowl rot.

nothing left.

lower quarter. I have an english wheel, but havenít had much success. but I have a fence and a stump, and two knees. you can make a quarter out of those.

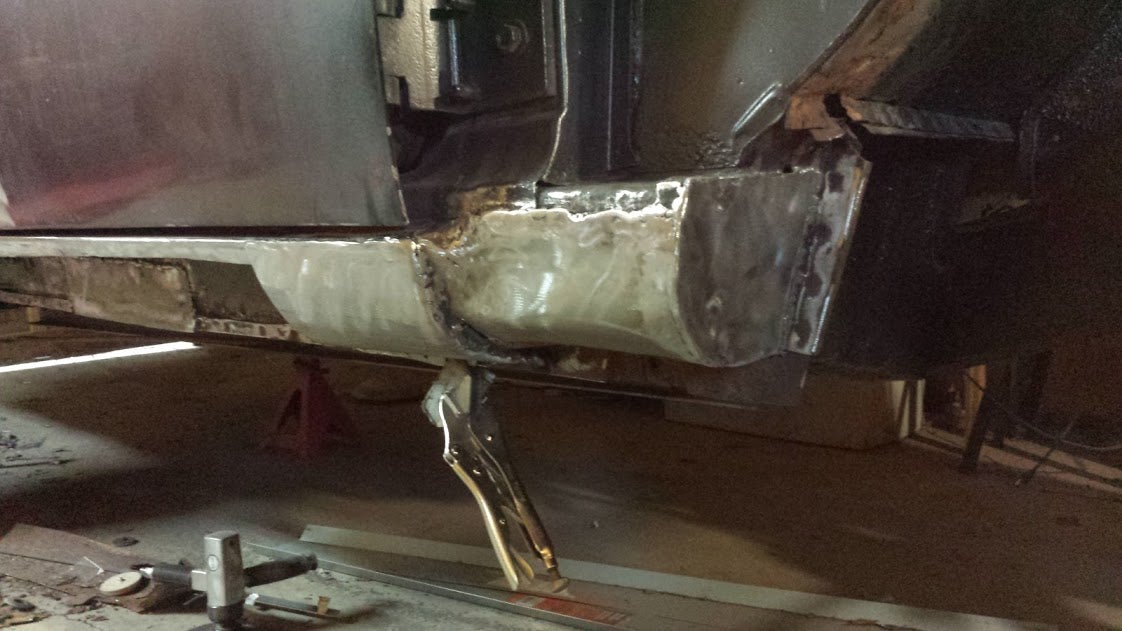

door corners and rocker in progress

9 feet of homemade mopar. yes thatís a yellow mach 1 up front. should be fixing that. But the customer grew up in the purple car, understands it canít really be saved, but still wants to drive around in it on sundays. Iím a sucker for that. And as Iíve said before I enjoy a challenge. Nothing I can do to this purple car will make it worse. couple pieces of flex-edging in there, but all beaten out of flat tin.

MM54

> Dash-doorhandle-6 cyl none the richer

MM54

> Dash-doorhandle-6 cyl none the richer

09/10/2016 at 12:58 |

|

Very nice work!

Iím hoping to do most if not all of the bodywork on my chevelle this coming winter; as far as I know the rust is limited to around (mostly behind) the rear wheels and the fenders behind the front wheels, but one I get in there Iím afraid to see how far it will go.

Having never replaced sheetmetal before, I may be soliciting some tips...

Dash-doorhandle-6 cyl none the richer

> MM54

Dash-doorhandle-6 cyl none the richer

> MM54

09/10/2016 at 13:06 |

|

Gimme a shout, Have never done rust on my chevelle, one of the reasons I like it. Luckiy, you should be able to source patch panels for 4 door chevelle, you can even get 4 door interior panels for these. Be patient welding. some patches are made to slip over top of the panel they replace and so are a little outsized. still best to cut and butt where you can.

MM54

> Dash-doorhandle-6 cyl none the richer

MM54

> Dash-doorhandle-6 cyl none the richer

09/10/2016 at 14:21 |

|

Iíve never been able to find patch panels for the rear quarters of a 4-door; I would imagine behind the wheel is the same as a 2-door but in front of the opening I have about 2" of metal whereas the 2-door has at least a foot. Fenders shouldnít be an issue and cowl pieces (if needed) I can make; like you said, I have a knee and a mallet.

Looking to pick up a Miller 211 in a month or two and some random sheet steel to practice before making a mess of my car! Looking to do it right so I donít have to do it again. Havenít welded sheet metal before so Iím looking forward to quite a learning curve!

Dash-doorhandle-6 cyl none the richer

> MM54

Dash-doorhandle-6 cyl none the richer

> MM54

09/11/2016 at 15:07 |

|

Forgot to mention I did and still do rust professionally for years. I also spent all my money on tools all those years. This car is not aiming for museum quality, just aproximate roadworthiness. A quick starter tip for driveway metalwork is this: gently cut out the piece with your zippy wheel, going a good margin into good steel that will actually weld. make a couple cuts if thereís curves or corners in the piece. pound flat and trace on the back of a cereal box. you will then have a piece that can be mangled back into the shape you cut out. if you get a blow hole, leave it and go back later. also a patch with round corners will warp less than a square one.

Dash-doorhandle-6 cyl none the richer

> MM54

Dash-doorhandle-6 cyl none the richer

> MM54

09/11/2016 at 15:08 |

|

also talk to 64mali. Heís doing some killer good work on a real basket case 4 door malibu.

MM54

> Dash-doorhandle-6 cyl none the richer

MM54

> Dash-doorhandle-6 cyl none the richer

09/17/2016 at 16:40 |

|

Thanks for the tips! (Sorry about the slow turn-around, have been out of town for work since Sunday afternoon)